Premier put system management.

In a light-directed sortation process, there is an interface between the put-to-light software and the user’s host enterprise resource planning (ERP), manufacturing execution system (MES), warehouse management system (WMS) or other software. The put-to-light system will download orders from the host; this data can often be shared in a variety of file formats.

From there, the put-to-light software tools manage the process, from creating operator work plans to configuring different modes and methods of sorting batches. The put-to-light software also addresses exceptions, such as when a scanned stock keeping unit (SKU) is not found in the order, shorting a SKU or custom order completion is necessary to complete the process.

During daily operations operators scan themselves into to their assigned put work station to track their daily productivity. During the sortation process operators press a confirmation button on the light module when puts for the scanned, active product to that location are complete. This transactional data is stored in a database, and the software provides advanced reporting tools enabling granular views of a facility, area/station or employee.

Put-to-light software features.

- Order management

- Work plans

- Order query

- Production overview

- Demand planning

- More (see advanced put-to-light software for more details)

Product Data Sheet: LP Dashboard

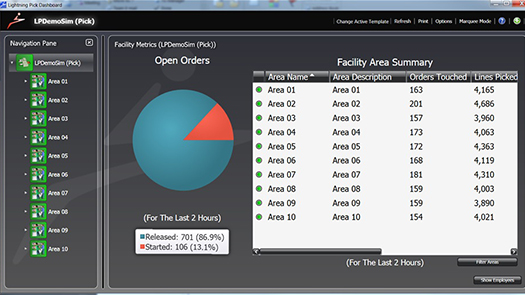

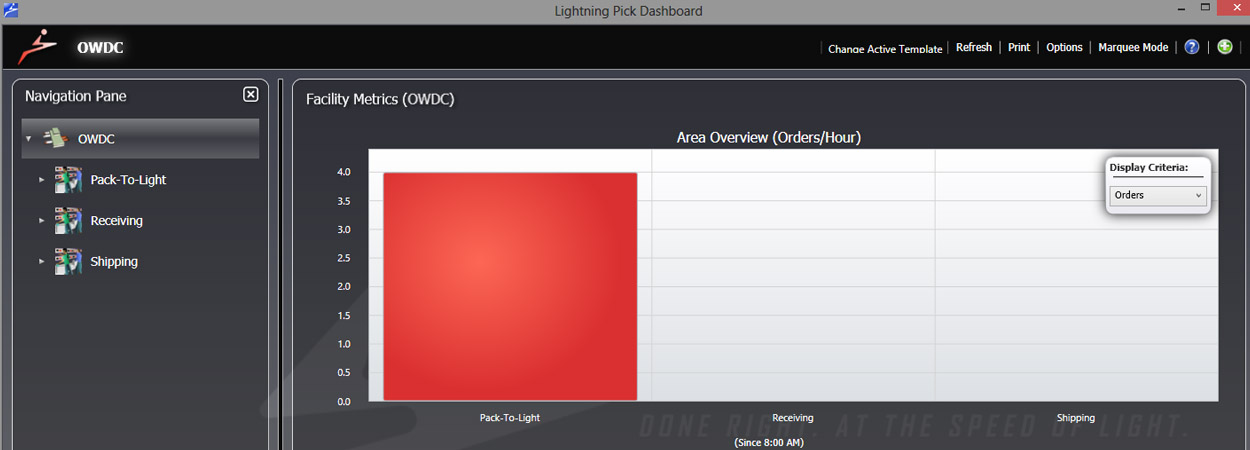

The LP Dashboard™ enables Lightning Pick users to easily view pick rate productivity, accuracy, throughput and other vital statistics in their order fulfillment or manufacturing operations through one centralized software application.

LP Dashboard’s next generation graphical user interface (GUI) enables users to visualize real-time metric data in a variety of high-impact graphical presentations. Intuitive navigation tools arrange valuable performance data into helpful chart and graph formats.